When you are deciding on the most appropriate industrial lubricant to meet your requirements there are plenty of variables you'll be required to consider. In this blog post we will look at some of the key factors you should consider in order to pick the best solution for your business. The first thing you must think about is the kind of machine that you are employing. Different types of machines require different types of lubricants in order to work properly. Always consult the instruction manual for your equipment or a professional before making a purchase.

It is also important to think about the operating environment of your machinery. If your machines are working under extreme conditions, it is essential to choose the right type of lubricant to stand up to those conditions. Another crucial aspect to take into consideration is the degree of wear that your equipment experiences. If your machinery is subject of wear and tear you'll have to select a grease that is able to withstand this type of use.

They help decrease friction and boost heat dissipation, as mentioned above. Additionally, they can also help remove contaminants that can create problems. Downtime is a major issue for any businessbecause it could result in loss of production and income. By maintaining your equipment by using industrial lubricants, you can reduce the possibility of interruptions. This is due to the fact that properly lubricated machines are less likely to suffer problems that need repairs or replacement.

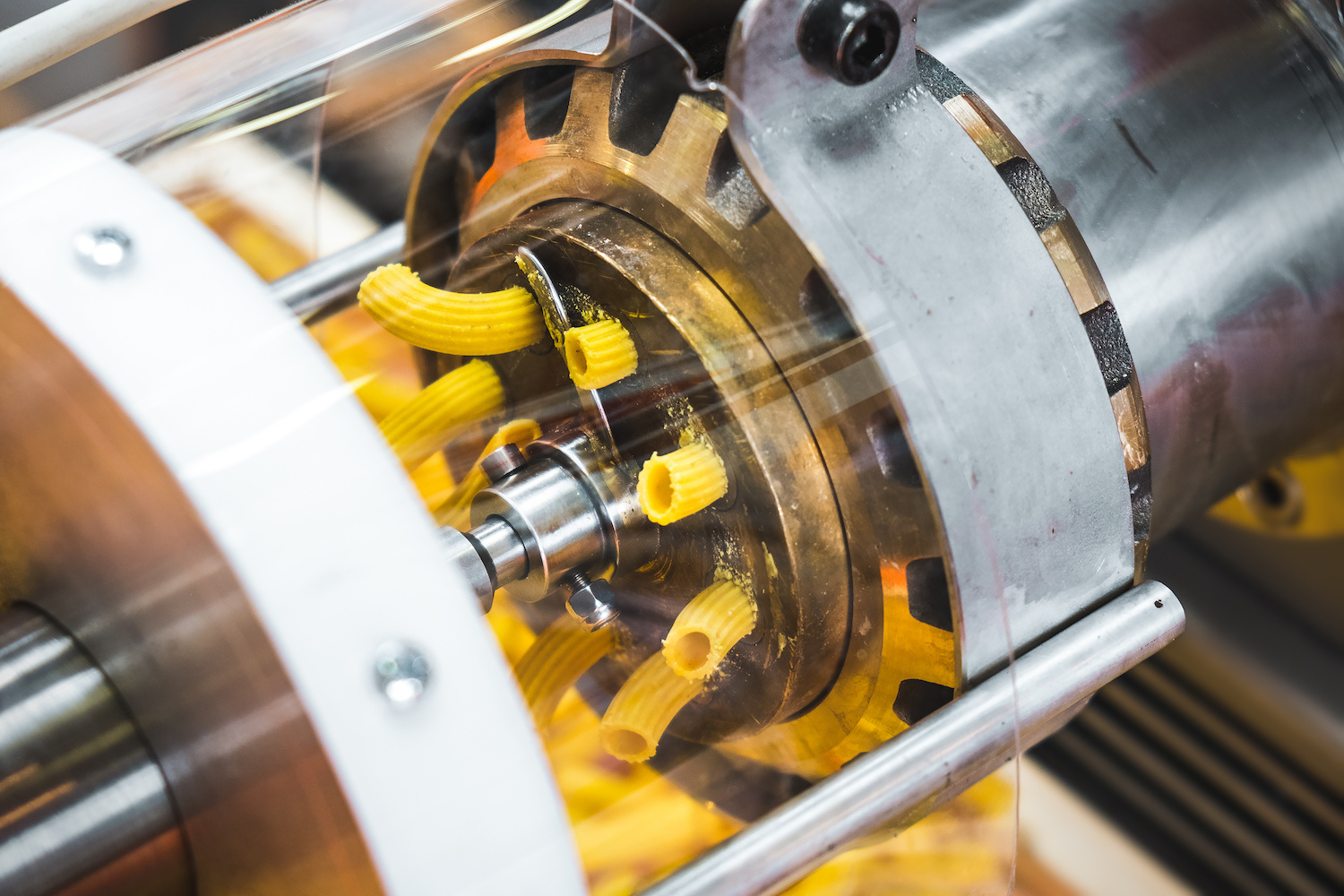

Turbine oil can be used to provide lubrificanti industriali. help keep these machines running efficiently by reducing friction and heat build-up. Chain and bar oil is utilized to lubricate chainsaws and other machinery that utilizes chains and bars. It reduces wear and tear on these parts and also reduces noise and vibration. Air compressor oil is used for lubricating air compressors. It aids in keeping the machines operating smoothly by reducing friction and heat build-up.Circulating oil is used to help lubricate pumps, motors, and other moving parts of machinery. To find added details please head to www.ronchi-ils.it/

If you believe your lubricant could be contaminated, it's crucial to take action right away. Try flushing the lubricant using a solvent that is clean. If this doesn't resolve the problem, you may have to replace the entire batch of lubricant. Another issue that is common to arise with industrial lubricants is foam development. This happens when air bubbles get trapped in the lubricantand cause it to degrade and can cause problems with equipment.

It helps reduce friction and prolongs the life of bearings through protecting them from wear and wear and tear. Chain grease is a particular type of grease that is specially designed for use in chains. It reduces friction and prolongs the life of chains by protecting it from the wearing and tear. Sprocket grease, a particular type of grease that is specifically designed to be used in sprockets. It helps reduce friction and improves the longevity of sprockets, by shielding them against wear and tear. Pulley grease is a specific kind of grease designed for use in pulleys. It helps reduce friction and prolongs the life of pulleys by